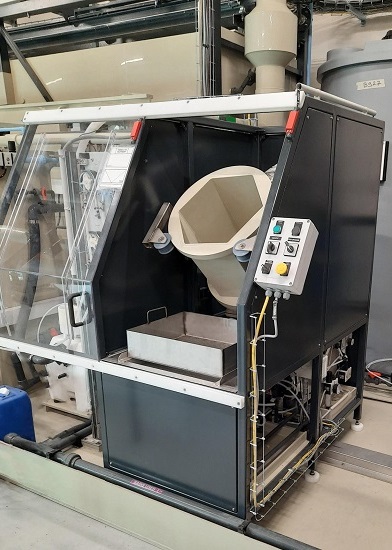

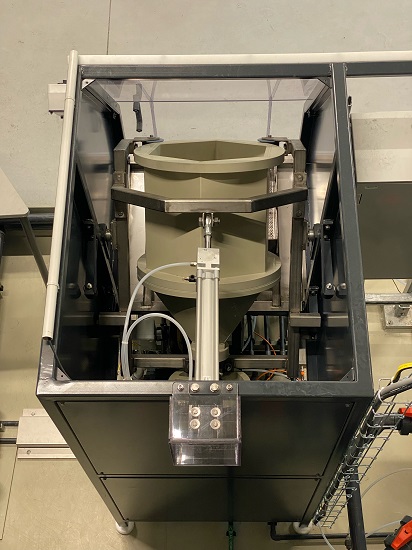

CORELEC Equipements has designed, manufactured and installed for a Lyon-based industrial company a complete surface preparation plant using spraying and painting (powder and liquid), as well as a 15L capacity immersion treatment bell barrel. It enables complementary chemical immersion surface treatment of small parts in bulk, thus limiting “operator” time (hooking/unhooking) on large scales.

This compact technology automatically circulates the products (active baths and rinses) in succession in the bell barrel, without moving the parts, and directly using the baths from the large-scale spraying tank.

This solution, which complements the fully automatic large-scale spraying system, reduces chemical handling and thus operator risks.

The bell barrel is automatically controlled by our LAQEXERT supervision and traceability software, enabling quality monitoring of the process.