With a constant focus on innovation and safety, our indirect heating systems, designed for surface treatment tanks, play a key role in optimising industrial processes while guaranteeing maximum safety. They effectively regulate the temperature of the liquids being treated, without direct contact with the heat source (such as electric immersion heaters).

The use of materials for heat exchangers, valves and piping such as 316L stainless steel, Uranus B6 or titanium means that they are chemically compatible with most treatments.

For more aggressive baths, we offer immersed heat exchangers, solid or lined in PVDF/PTFE, directly in the tanks.

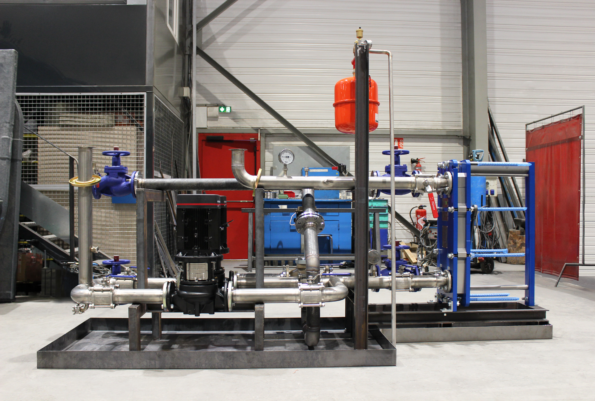

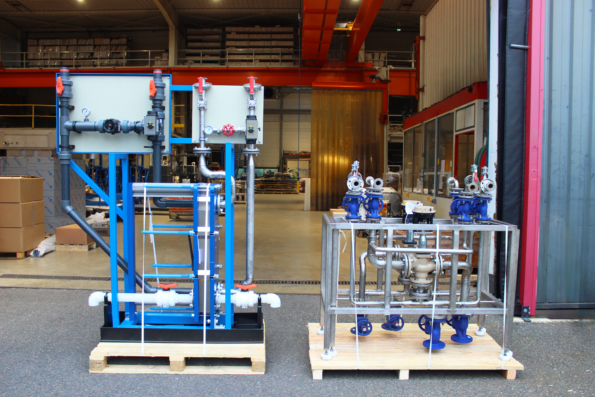

Safety and energy efficiency are at the heart of our approach. With skid heat exchangers, we offer a heating system that protects the tanks from direct overheating and guarantees optimum energy management. What’s more, the skids’ modular, compact design means they can be installed quickly and integrated easily into existing infrastructures.

At CORELEC Equipements, every project is unique. Our Design Office designs and manufactures fully customised heating or cooling solutions to meet our customers’ specific needs.

Don’t hesitate to contact us to find out more about our tailor-made solutions!