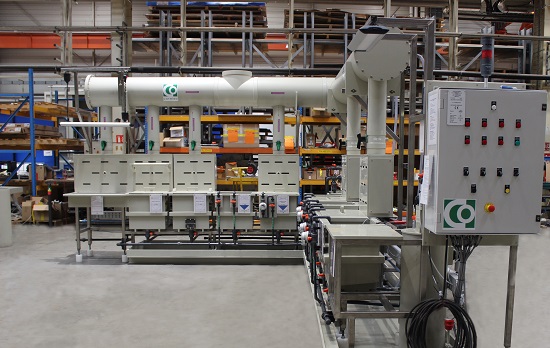

CORELEC Equipements has built for one of the world’s leading bearing manufacturers, a non-destructive testing manual plant using the nital etch inspection process.

Nital etch inspection is a special process used to detect structural heterogeneities on steel parts, by immersing them in various water and acid based booths (solvent-free).

The final visual inspection is based on the colouring obtained after etching to detect any defects.

This installation will be integrated into our customer’s R and D centre, enabling the production of various prototypes in preparation for future industrialization.

This design, based on modular stands, enables rapid on-site assembly, with pre-assembled equipment (piping, electrical ventilation, etc.) delivered in blocks.